5 Label Designs We Are Obsessed With

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary Labelers

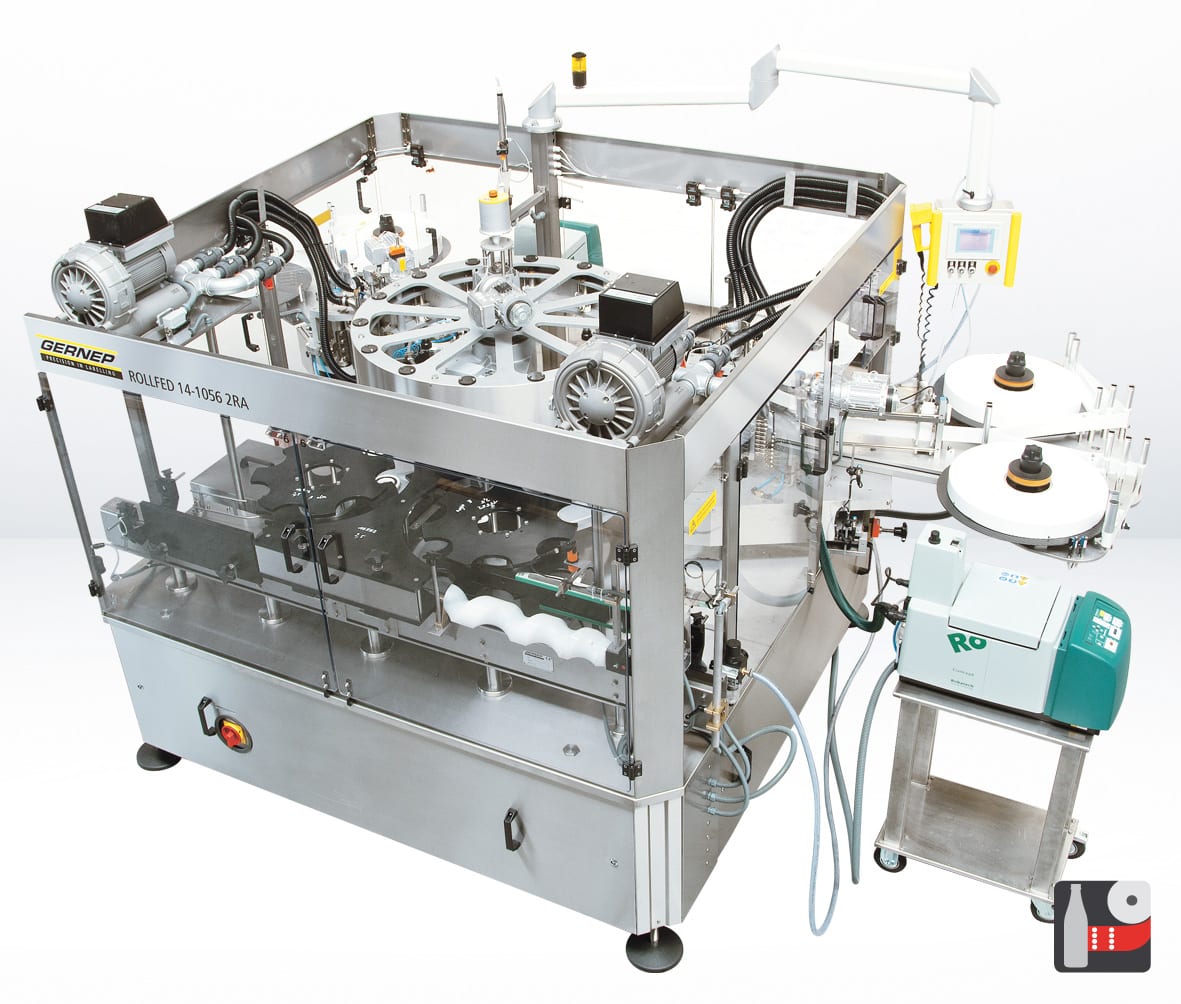

Patented overlay gearbox for label adjustments without machine interruption

Paper and foil label processing capability

New GERNEP HotSpot nozzle system for hot melt applications

Controllable & adjustable start-gluing as spot-application

Variable control & adjustment of end-gluing with end-gluing ledge or spot-application

Avoid continuous cooling & reheating that causes condensation in standard roller gluing systems du to the closed hot melt system.

Robust torsion-resistant Rollfed aggregate tripod with adjustable scales for precise & repeatable aggregate/label positioning

Mechanical coupling synchronizes bottle table & roller unit

No bottle – no label – no glue – automatic

Optimized brushing minimizes spiral offset of longer labels

Radially adjustable machine hood for container tolerance compensation

PLC controlled servo drive feeds label material for maximum labeling accuracy

Automatic splicer or additional roll holder for extended or uninterrupted operation (optional)

Hot Melt is a polymer-based adhesive that is an excellent alternative to waterbased-glue because it is fast-acting and withstands humidity. This labeling technology has been the preferred method employed in bulk production that requires high output demands with a fast set speed and the ability to meet and maintain a high level of hygiene.

Holt Melt Labeling is especially appreciated in the cold food industries that need product packaging labels that adhere quickly and easily, conform to various types of packaging, and stay in place for the product’s life cycle. One of the greatest benefits of hot melt adhesives is that they deliver unmatched versatility for any temperature application – warm or cold.

The term “roll-fed” illustrates the type of label and the way it is fed into the labeling machine. It describes the label as a substrate made of film or paper on a continuous roll without a liner or adhesive pre-applied. A desirable side effect of using hot melt roll-fed labels is reducing waste and promoting high application rates. Labeling machinery cuts the film into individual labels as it is dispensed for each container, then adds an adhesive as the label wraps around it. Roll-fed labels use fewer materials in the application process, and the cost difference is noticeable with any production size but gets more substantial with larger production runs.

The greatest advantage of this type of labeling is that packaging is appealing on every side; 360-degree coverage may provide that extra visual impact to attract customers. Label rolls can be prepared in full color and even enhanced flexographic printing.

Our explicitly designed fully automatic labeler enables the economical wrap-around labeling of glass, plastic, and metal containers.

Due to its modern and operator-friendly circular design, the ROLLINA can operate hot melt labeling from the magazine. The Rollina-R is a combined thechnology labeling system and comes equipped with other aggregates for pressure-sensitive and/or cold glue labeling.

We are obsessed with the ingenuity of these 5 product label designs that artfully convey the spirit of their product....

04 May, 2022 Bottle Labeling Design Rotary LabelersSpoiler – Weather and temperature affect labeling! Here are 5 common temperature-related issues to help you troubleshoot your labeling issues....

28 February, 2022 Rotary Labelers Trouble Shooting